MTU Maintenance & AGSE® Sign a Letter of Intent to Cooperate on Engine Stand Leasing

Amsterdam, The Netherlands–October 2023

MTU Maintenance Lease Services B.V., a subsidiary of MTU Aero Engines AG specializing in engine leasing and asset management, and Advanced Ground Systems Engineering™, LLC (AGSE), an industry-leading designer and manufacturer of trusted aerospace ground support equipment and tooling solutions, have signed a letter of intent to cooperate as equal partners to offer engine transport stands for lease starting in January 2024.

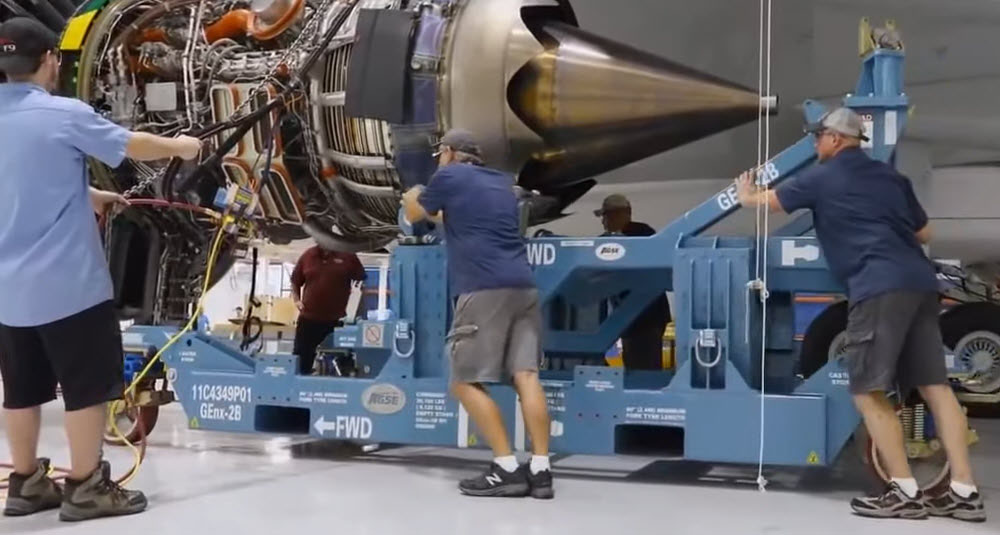

California-based AGSE will produce and supply transport stands for a variety of engine models, including but not limited to CFM International’s LEAP and CFM56, International Aero Engines’ V2500, and Pratt & Whitney’s GTF™ engines, in addition to wide-body models such as GE Aerospace’s GE90-110/115B, GEnx-1B and CF6-80, and Engine Alliance’s GP7000. The leasing branch of MTU Maintenance, the global leader in customized maintenance, repair, and overhaul (MRO) solutions for aero engines, will handle all commercial leasing aspects of these stands.

Patrick Biebel, Managing Director at MTU Maintenance Lease Services, says having AGSE as a partner is the logical choice. Given its extensive engine stand portfolio, the manufacturer fits seamlessly into the leasing company’s ambitions to expand its capabilities and the MTU Maintenance ServicePlus suite of products. “It’s all about a one-stop-shop principle where MTU Maintenance has the right setup to support its customers with any engine-related issue. This stand leasing service enables us to be even more responsive to our customers across the globe,” says Biebel. “AGSE is globally renowned as the leading independent stand manufacturer with a top-quality product.”

Eric Henderson, Vice President of Strategy and Business Development at AGSE, says MTU Maintenance shares the essential values his company seeks in a partner: an unrelenting focus on product quality and customer service. “With its global leasing infrastructure and MRO network support, MTU Maintenance Lease Services can deliver the right stand to the right location for our customers,” says Henderson. “We see an increasing demand for more flexible solutions, so it makes sense to partner with a global player such as MTU Maintenance to expand our services further and provide an engine stand leasing solution.”

Earlier this year, Amsterdam-based MTU Maintenance Lease Services celebrated its 10th anniversary. In recent years, the company expanded its expertise beyond the core engine leasing and asset management services, such as parts trading and engine and module exchanges. It also offers engine lease pool management with CORTEX Lease, MTU’s in-house developed software, and technical asset management, which includes technical consulting and end-of-life solutions for assets.

AGSE is celebrating its 50th anniversary this year, reflecting a history supporting the industry's most extensive portfolio of engine transportation stands and Ground Support Equipment. Additions of the Stanley Aviation brand with its Aircraft Towbar portfolio and launching AGSE Tooling, its Engine Tooling Division in Ohio, have expanded its product coverage to support its global customers.

About MTU Aero Engines

MTU Aero Engines AG is Germany’s leading engine manufacturer. The company is a technological leader in low-pressure turbines, high-pressure compressors, turbine center frames as well as manufacturing processes and repair techniques. In the commercial OEM business, the company plays a key role in the development, manufacturing and marketing of high-tech components together with international partners. Some 30 percent of today’s active aircraft in service worldwide have MTU components on board. In the commercial maintenance sector the company ranks among the top 3 service providers for commercial aircraft engines and industrial gas turbines. The activities are combined under the roof of MTU Maintenance. In the military arena, MTU Aero Engines is Germany's industrial lead company for practically all engines operated by the country's military. MTU operates a network of locations around the globe; Munich is home to its corporate headquarters. In fiscal 2022, the company had a workforce of more than 11,000 employees and posted consolidated sales of 5.3 billion euros.

Your contact at MTU Maintenance:

Saša Lakić

Media Relations Manager MRO

Mobile: + 49 (0) 170 549 1691

Email: sasa.lakic2@mtu.de

For a full collection of press releases and photos, go to http://www.mtu.de

About Advanced Ground Systems Engineering (AGSE)

AGSE, now celebrating its 50th year of service, is a global leader in the original design and manufacture of innovative aerospace ground support equipment and tooling. Headquartered in Los Angeles, California, USA, our experienced staff delivers the most robust offering of trusted, custom-designed, and OEM-approved products for safely handling the top jet engines and aircraft used in commercial and military aviation. Westmont Industries, AGSE's parent company, is dedicated to designing, manufacturing, and installing high-quality engine gantries and specialty industrial equipment. AGSE Tooling, founded in 2014 and based in Cincinnati, Ohio, USA, is proudly licensed to support LEAP & CFM56 tooling requirements for line, hangar, and shop maintenance.

Your contact at Advanced Ground Systems Engineering:

Torsten Mangelsdorf

Director of Sales, Europe

Mobile: + 351 932 085 158

Email: tmangelsdorf@agsecorp.com