Why Use OEM-Approved Spare Parts?

PRESERVING SYSTEM INTEGRITY

IN AN OEM-APPROVED CONFIGURATION FOR ENGINE

GSE & TOOLING

Shipping stand components work

together as a complete system

to handle a jet engine safely.

A CHAIN IS ONLY AS STRONG AS ITS WEAKEST LINK

This centuries-old proverb depicts a single inferior part risking a whole’s integrity, quality, or effectiveness.

It is a concept not lost on GSE & Tooling OEMs: tinkering with their highly engineered systems’ expertly

crafted and officially tested certified parts significantly compromise their safety and functionality.

WHAT IS OEM-APPROVED?

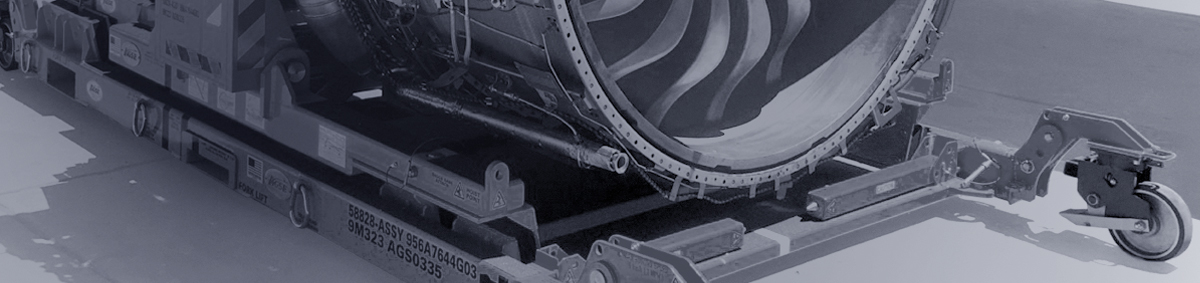

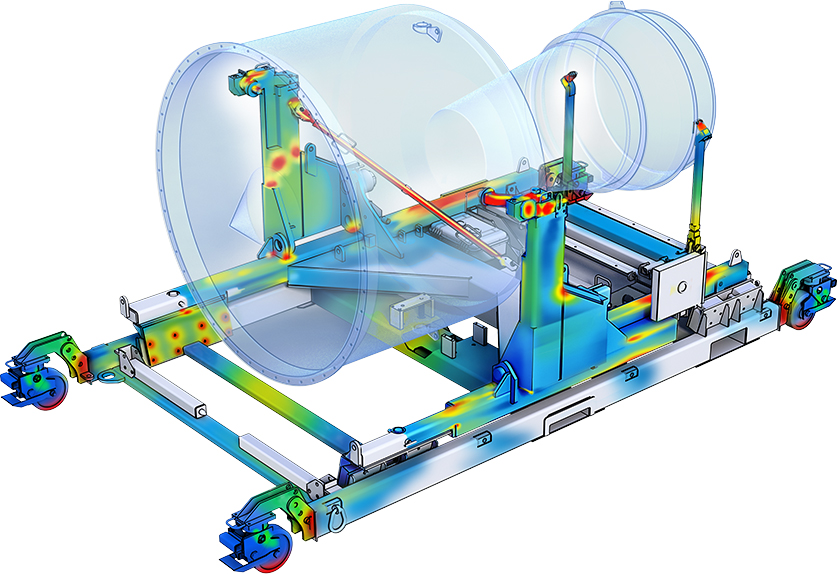

Engine GSE & Tooling, tasked with the critical handling and transportation of jet engines and their modules for line or shop maintenance, operate as systems comprised of many assorted parts working in conjunction with each other. The manufacturers of these jet engines, the Engine OEMs, license and approve the proprietors of these solutions, GSE & Tooling OEMs, to design, build, test, and qualify every system component to their precise specifications. It guarantees that all its parts fulfill their function in the system, achieving long-lasting protection for the engine asset and optimal safety for the end user.

A NOT-SO-PERFECT WORLD

However, like any tooling in the field, exposure to accidents, improper maintenance, or user error can usually lead to damaged, expired, or lost parts, adversely impacting the overall system’s performance. Such mishaps prompt the end user to replace or modify the original parts to keep their equipment in service. Is it okay to use merely any replacement part? Furthermore, is it prudent to assume that any commercially available material can supplant components purposely designed to support a multimillion-dollar jet engine competently?

THE MANY DANGERS OF NON-OEM SPARE PARTS

Procuring spare parts through non-OEM-approved sources to save on maintenance costs should not be an option for owners and operators. Any in-house alteration, reengineering, or reproduction of a simple part, like a safety pin, or purchasing a more intricate component, like a caster assembly, through a third-party supplier obstructs system integrity.

Replicating or subcontracting replacement parts based on similar functionality or approximate dimensions of an original part just so it can fit within the system ignores a multitude of essential product compliance guidelines set forth by the Engine OEM, which include detailed:

Such practices open the possibility for tooling failure, risking the end user’s safety and the engine’s integrity when accounting for the strains on the system’s load, handling, and surrounding environment. In addition, unauthorized modifications likely incur higher replacement or repair expenses since they void the Engine OEM and the GSE & Tooling OEM warranties, render long-distance transport uninsurable, or force the system into abrupt or early retirement.

PEACE OF MIND

OEM spare parts for Engine GSE & Tooling are designed and manufactured explicitly for their intended applications and maintain the OEM-approved configuration. They are the same parts as those installed during the initial manufacturing process, allowing for a correct, instead of approximate, fit within the system to expedite the ease of replacement. Unlike non-compliant counterparts, their certified, diligently tested, and superior quality guarantees durability and reliability, especially when working with other system components and subassemblies. This unrivaled quality exclusively preserves the system’s safety, functionality, and integrity over its life cycle, helping avoid unwanted repair or replacement expenses later. Most importantly, OEM spares are readily available by the GSE & Tooling OEM, which offers dedicated round-the-clock customer service and makes locating the correct part hassle-free.

CONCLUSION

Keeping GSE & Tooling in its OEM-approved configuration through OEM-approved and sourced parts is of prime importance. Otherwise, the tooling, personnel, and engine assets these systems handle can face grave risks. Continuously optimize the equipment’s integrity and serviceability by: